|

|

Post by jspbtown on Mar 7, 2011 13:05:35 GMT -5

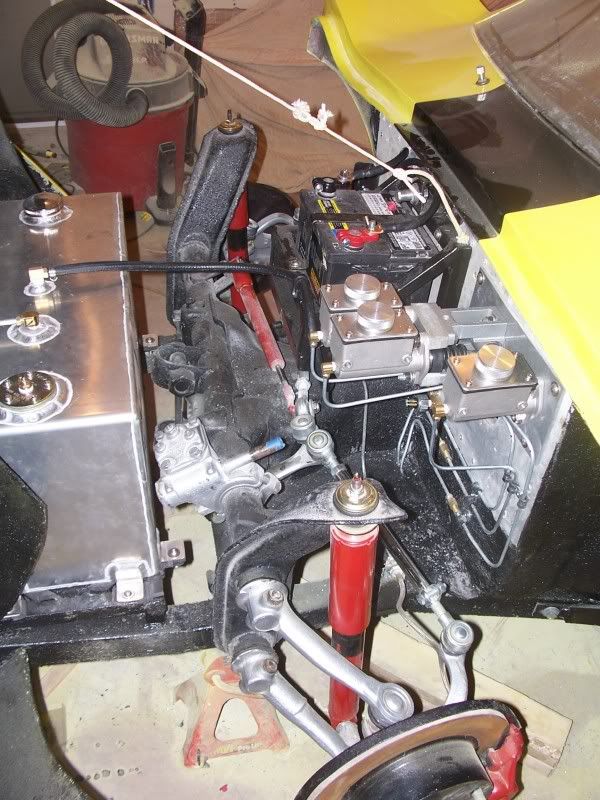

I got all the brake lines run, one headlight bucket rebuilt, one headlight bucket primed, and discovered that the slave cylinder that I had hoped would be fine (after sitting outside for what looks like decades with a brake fluid gel in it) was in fact not fine. I ordered a replacement today.

I also mounted the battery and welded in a nice grounding nut.

I went to take some pics but my battery was dead. Maybe tonight while my son is at practice.

|

|

|

|

Post by jspbtown on Mar 15, 2011 13:54:59 GMT -5

Been out a little more regularly lately. Things were going well, but last night was a drag.

Nothing went well.

My 3 CNC reservoirs don't work despite being rebuilt. I think they were just so corroded that they won't seal up. No matter what I do I can't get them to push any fluid. So...new ones ordered.

I broke a little cheap throttle cable I had and ordered a nice heavy duty one, only to find out that it doesn't fit in the sheath. Oh well.

I tired to cover the storage area I built in felt but its a no go. I am just not good enough. Looks like I will need some other options. Suggestions?

All in all it was about 3 hours of work and I didn't accomplish much.

|

|

|

|

Post by smyrnaguy on Mar 15, 2011 18:45:59 GMT -5

What type of felt were you using? Most aren't very suited for upholstery with the exception of some industrial felts. They are great for padding, insulation and damping but tend to become beady with rubbing. Cotton and blended felts will stretch and bend to shapes with heat and steam. Best adhesion is with contact cement. A better fabric might be a heavy wool, tweed or leather remnant dyed to color.

|

|

|

|

Post by jspbtown on Mar 22, 2011 13:13:48 GMT -5

smyrnaguy...I was using freakin junky felt! I hate interior work. I suck at it. I have another idea that I am going to try. I will report on that once I get the material.

Got the headlights all rebuilt and the fuel tank with sender installed. I also got the aluminum grill work done (I like it!).

Next step is to run some fuel lines (I think I am going to need an electric pump) from the tank to the line, get those pesky rear storage areas done, and then off to the wiring.

|

|

|

|

Post by gerrym1030 on Mar 25, 2011 8:08:17 GMT -5

jspbtown, car looks great! I am working on one of these as well, so the pictures of what you have done has been very helpful! Can you let me know what hinge you used for the back hood? I too am having trouble with getting it hinged properly and out of the way of the muffler, etc...

|

|

|

|

Post by jspbtown on Mar 25, 2011 9:23:13 GMT -5

I wish I could remember.....it was so long ago. I am thinking they may have been Neon trunk hinges. I know they were trunk hinges form some cheapo car. They cost me $20 on Ebay.

Last night I was able to get the new black indoor/outdoor carpeting installed in my little storage areas. MUCH better than the felt. I also made some templates for the carpet to go around the back. Once I get that who rear section done I can start wiring.

|

|

|

|

Post by gerrym1030 on Mar 25, 2011 11:06:08 GMT -5

Do you have a wiring harness? If not I just installed the one from CIP1.ca or if you are in the US CIP1.com. It saved me a tonne of time and it's a very good quality and comes with a wiring diagram. Gerry

ACC-C10-5720 - UNIVERSAL HARNESS WITH FUSE BOX - FOR DUNE BUGGY - KIT CAR - CUSTOM APPLICATIONS

|

|

|

|

Post by gerrym1030 on Mar 25, 2011 11:08:40 GMT -5

Regarding the hing, I can just see a ford stamp, looks like there might be a number on there as well, that would help. Just makes sense to get a set that someone has already got working... Also, do I see a hydraulic cylinder in that picture? Gerry

|

|

|

|

Post by jspbtown on Mar 25, 2011 11:51:38 GMT -5

Gerry, I am not a big fan of those empi kits. I like the newer style fuse blocks and fuses personally. Wiring is one of my favorite parts of the build. I picked up a very nice 18 circuit wiring kit for $75 off craigslist that I will be using. I need a few extra circuits because I am using linear actuators to open the front and rear hatches, I have electric bear claw latches for the front and rear, and power windows. It comes with a decent diagram that I can follow but since every wire is marked I should be able to get it done. Yeah...those hinges came with little gas struts. I won't be using them since I have the actuators. I will look at them this weekend and post any identifiable marks or numbers for you. Might be Ford Focus: cgi.ebay.com/ebaymotors/2000-Ford-Focus-Left-Rear-Trunk-Hinge-Strut-_W0QQcmdZViewItemQQhashZitem3c9687857fQQitemZ260223501695QQptZMotorsQ5fCarQ5fTruckQ5fPartsQ5fAccessories |

|

|

|

Post by gerrym1030 on Mar 25, 2011 15:54:39 GMT -5

Since you are not going with the hinges I should ask before I track some down, did you like the way it opened? I wouldn't want to proceed if you didn't like the results. My challenge is getting it open far enough to get to the engine and not hit the exhaust system.... I have my car lifted in the back by about 3 inches (I'm 6'2") so the tail section doesn't open under the exhaust.

Thanks for the feedback, and keep the pictures coming, I would like to see the interior, the console looks really neat. Gerry

|

|

|

|

Post by jspbtown on Mar 25, 2011 20:59:33 GMT -5

I am going with the hinges...just not the little hydraulic supports since I am using the actuators. Yes to hinges and yes to actuators.

I like the way they work, and I am hoping they clear my engine/exhaust. Right now I have neither installed so I can't let you know if they are the answer or not.

|

|

|

|

Post by jspbtown on Mar 27, 2011 20:34:00 GMT -5

|

|

|

|

Post by Gary Hammond on Mar 27, 2011 22:26:10 GMT -5

Hi Jeff,  NICE WORK!! ;D ................ I greatly admire the skill and tenacity displayed in your many projects, and the experience you so willingly share with the rest of us.  Gary Hammond,   |

|

Minax

Junior Member

Posts: 61

|

Post by Minax on Mar 27, 2011 23:27:54 GMT -5

Sweet!!!

Wish I had more time and money to work On my GTII but at least I get to see what else is going on out there..

Looks Awesome!!!

|

|

|

|

Post by big bob on Mar 28, 2011 8:58:01 GMT -5

woow!

jeff that is awesome. very professional. i love a neat install

big bob

|

|

|

|

Post by Jeff Troy on Mar 28, 2011 11:42:46 GMT -5

Hey, Jeff,

Outstanding, my friend. But I wouldn't have expected anything less from you.

Warmest...

|

|

|

|

Post by jspbtown on Mar 28, 2011 12:55:38 GMT -5

Thanks guys. Its coming along....slowly. I am starting to get back into the stuff I enjoy.

The fuel tank also has 1" straps that go over the top and are bolted into the steel frame. I just need to paint them up which means I need to do them outside cause I can't move the Avenger yet.

The wiring will run down the center console and feed the switches and such on the dash & console. I have a set of white VDO gauges and a Flaming River tilt column to round things out. Since I picked up a set of Corbeau seats for my Deserter buggy I think I might use my Tenzo seats for this project.

|

|

|

|

Post by jdhicboy on Mar 29, 2011 8:15:50 GMT -5

Great job, very impressive work. Hope to see more pic as it comes along. Your car is a great motivator to do my GT2 right the first time.

|

|

|

|

Post by jspbtown on Mar 30, 2011 14:43:37 GMT -5

Picked up my switches yesterday. I was really torn on what to get. I needed several DPDT momentary switches for the windows and linear actuators, as well as some DTDT non-momentary ones for the headlights and wipers. I wanted to get all the same but was having a difficult time getting what I needed in the same style. I didn't want anything too big or bulky.

I ended up getting some nice simple toggle switches from my local Radio Shack. I think they will go with the period of the car, and I didn't get burried on the cost. There are 6 in total so I need to lay my dash out, and I will have 6 indicator lights as well (turn, hi beam, alternator, and 2 for the actuators which will light when the hatches are not complete closed.).

|

|

|

|

Post by jspbtown on Mar 31, 2011 9:40:34 GMT -5

I am trying to guess if I will need an electric pump (with regulator) for my Avenger project. Here are a couple of pictures of my set up:   The tank is custom. The metal line that comes out from the top is a vent line. it goes over the top of the tank toward the front, does a 360 degree loop, and then exits below the vehicle. The rubber line is 5/16". There is an aluminum line in the tank that goes to the bottom of the tank. It connects to a barbed fitting, through the rubber line, and into a new 5/16 line that enters the tunnel under the battery (the stock location), is run inside the tunnel and exits in the rear at the stock location. My concern is whether the stock VW pump will be able to pull fuel up through the top mounted supply line. I probably should have designed a bottom mount supply port, and still could possibly have that done, but it might be the same cost as a pump and regulator. My wiring harness has a circuit for the electric pump (it would be wired through a safety switch) and I could mount the pump in front of the battery with ease. So....thoughts? Will a stock pump be able to draw the fuel up the tank and to the motor? |

|

|

|

Post by Gary Hammond on Mar 31, 2011 10:22:19 GMT -5

Hi Jeff,  The stock pump should be able to pull enough vacuum to lift the fuel against the small "head" in the tank and the resistance in the line. Especially if the line is full of fuel. However, vapor lock is very likely to result in warm weather. Also, the fuel may drain out of the line and back into the tank if the tank is less than full and sets for several hours or days. This would require the pump to refill the line before filling the carburetor. AKA....Lots of cranking required to start!  It is much better to install an electric pump near the bottom level of the tank and then "push" the fuel through the line. This will pretty well eliminate "vapor lock" and fuel drain back into the tank. And by letting the pump run for a few seconds with key on before going all the way to start, fuel refills the line and carburetor for a much faster start and longer battery and starter life.  ;D Gary Hammond,   |

|

|

|

Post by smyrnaguy on Mar 31, 2011 10:23:41 GMT -5

The stock pump should work fine. Few cars have a bottom fuel outlet on the tank, most are on top. A bottom outlet might present problems as any crud or water would find its way into the fuel system immediately where as a top outlet and interior fuel sock type can accumulate nearly an inch of junk in the bottom before lines or filters clog up.

|

|

|

|

Post by jspbtown on Mar 31, 2011 10:32:34 GMT -5

The stock VW system has the outlet on the bottom and is the same height (approximately) as the fule pump so it gets some help from the weight of the gas pushing the fuel through the lines to the pump. Thus the reason for my concern.

|

|

|

|

Post by Gary Hammond on Mar 31, 2011 11:11:40 GMT -5

Hi Jeff,  The top outlet tank still draws fuel from near the bottom of the tank .............basically the same height as a bottom outlet tank. So, essentially no difference except for the amount of residue that may enter the line. The fact that the tank is lower than the pump is where the problem might come in. You will have the same issues with the outlet in either place!  .....................If the tank is mounted higher than the engine it will gravity feed with either system as long as the vacuum is not broken in the draw tube of the top outlet design! (The draw tube becomes part of a siphon.)  Any time you ask a mechanical pump mounted to a hot engine to "pull against a head" or "pull a significant vacuum", because of tank location, you may encounter the issues I listed in my previous post.  Gary Hammond,   |

|

|

|

Post by jspbtown on Mar 31, 2011 11:20:58 GMT -5

Interesting...Thanks Gary. It might just make sense to leave the wiring in place for an electric and give the old standby a shot.

I can easily coil the pump hot lead and ground up under the battery until such time I try getting it running.

|

|

|

|

Post by centralvalleygter on Mar 31, 2011 11:36:03 GMT -5

Just to communicate my experience with electric fuel pumps on ACVW. Both my BAHA and Bradley had/have electric fuel pumps IN PLACE of the MECHANICAL one. My bus has only the stock one. In the 25+ years I had my BAHA I had to replace the pump once. The original was a solid state pump, the second was a traditional motor powered one. Both worked great. I think I originally put in the electrical one when I put on the alternator and the stock fuel pump would no longer fit (I know I could have gotten a later model or other after market mechnical pump, don't know why I didn't, but I had a reason at the time). The one on the BAHA was in the front below the tank and "pushed" the fuel. I currently have a solid state electric fuel pump on the Bradley-mainly because the engine in it is from the BAHA, which doesn't have a mechanical fuel pump.

My point, I have been using an electric fuel pump for years without any problems and at this point prefer them.

Warmest Regards,

|

|

|

|

Post by rebel67 on Mar 31, 2011 12:46:13 GMT -5

In my experiances on a lot of different cars, I will reccommend the electric as well. Low failure rate, good pressure, and adaptable to any system, above or below levels. Not to mention consistant pressures, once you try it, you will like it!

|

|

|

|

Post by gerrym1030 on Mar 31, 2011 13:09:11 GMT -5

I am having this very problem with fuel right now on my Avenger, I was about to break into the stock fuel pump to see what is up, but based on some of these comments, decided the $75 for an electric pump was the way to go and have the least amount of issues later on. Not being able to start your car after a long hot day at the car show would be rather embarrassing! Just wanted to add my thanks to the Bradley GT car club for allowing this post to continue! I have gotten a lot of good ideas from this thread. Attachments:

|

|

|

|

Post by jspbtown on Apr 1, 2011 8:48:05 GMT -5

I got the rear lights installed and wired up last night (other than the grounds). Thats 4 rear lights (2 blinkers, 2 brake & 4 driving lights), two back up lights & license plate light. I still need to wire the actuators, the bear claw latches and indicator switches.

I also started laying out how my wires will be installed in the front end.

The wiring plan I am following is to wire all the lights, then the actuators, then the windows, then the grounds, and lastly the dash. The dash will use all plug ins so I won't have to be on my back working upside down.

|

|

|

|

Post by rebel67 on Apr 1, 2011 9:12:39 GMT -5

Simply awesome. I hope that it finishes as well as its been going, and I know it will be a real head turner anywhere you take it!

Just wanted to collaborate with gerrym1030 and say what a great deal of info just this thread has given. Your descriptive addittions are just as important as the pics. Ever think about writing a book? Would go great with Jeffs CD!

-Mike

|

|