|

|

Post by Dan MacMillan on Apr 5, 2013 18:28:19 GMT -5

Well this winter has been a bust for working on anything. I had started converting to power brakes on the GT2 but then lifes little things took over. Next thing I knew it was our mid winter thaw and the floor of the garage got flooded, again. Then it froze. No damage but everything is stuck down. I am hoping to get out there next week and start the thawing process and get back to work on the conversion.

I am also supposed to be building a 1641 dual carb VW for a friend's buggy that I repaired last summer. The parts have been sitting in my house for 2 months.

WINTER SUCKS. Wish I could put a dome over my property {would be easier than moving} so it would be summer all year.

|

|

|

|

Post by skip20 on Apr 5, 2013 21:26:34 GMT -5

This I got to see!!! ;D

|

|

|

|

Post by cocacoladodge on Apr 23, 2013 16:36:59 GMT -5

I was thinking of a different brake setup as mine went out again. (the seals for the fluid inlet are shot in the n.o.s. master i had so much headache benchbleading last year...)

I have a mostly stock 68 singleport 1500 (vac adv distrbutor) - would I need to get a vacuume pump and reconfigure the pully system ad run a hardline fom back to front to run powerbrakes, or just have a small electric moter powered vac pump up front?

Please post pics when your doing it if you can.

|

|

|

|

Post by Dan MacMillan on Apr 23, 2013 17:02:34 GMT -5

Actually you do not need a vac pump, Depending on what carb you have there may be a large por on it, usually at the rear that is manifold vac {mac vac at idle that drops as he rpm's are increased} This port is only used on dual vac distributors. If you do no have one you can add one to the intake runner {braze weld a 3/8" port that a check valve can be attached to.

I am just now getting the water out of my garage and plan to resume work on it this weekend. I will be posting photos and updating.

|

|

|

|

Post by Dan MacMillan on Apr 23, 2013 17:08:38 GMT -5

Do you want to see 1 engine build 2 brake upgrade 3 dome over property |

|

|

|

Post by rizzo81 on Apr 30, 2013 13:46:45 GMT -5

Dome over property! Bio dome lol!

|

|

|

|

Post by Dan MacMillan on May 30, 2013 20:50:16 GMT -5

Sorry for the lack of photos but here is an update. They work great.

I decided that I was going to flat tow my GT2 to Niagara on the 21st of June so I constructed a subframe to allow the use of a tow bar. I just finished it up along with the brake conversion. So far did a little test in the driveway, now I can hold it in place with minimal pedal effort and the brakes apply much easier. As I used the Subi auto trans I will have to disconnect the driveshafts to flat tow but it will make my life easier. Normally I do not tow my cars but due to the hybrid axles and limited driving I put on the car since the Subi conversion, I chose not to take a chance on a break down involving one of a kind parts. I still have a bit of work on the subframe that will happen on Monday. I promise that this time I will take pics of the transformation.

|

|

|

|

Post by Dan MacMillan on May 30, 2013 20:54:53 GMT -5

I ended up running a dedicaed brake vac line as the setup for my temp controls was not fast enough. I threaded a Toyota brake booster check valve into the intake manifold runner { can be done to a VW 1600 dp end casting} and ran a 3/8 steel line to the booster.

|

|

|

|

Post by skip20 on May 30, 2013 22:40:33 GMT -5

Check out the EV cars.

The sell a Vac pump to use for your P/S

|

|

|

|

Post by Dan MacMillan on May 31, 2013 18:00:49 GMT -5

Why use a vac pump when the engine supplies an endless supply that does not cost you in horsepower.

|

|

|

|

Post by Dan MacMillan on Jun 6, 2013 20:52:47 GMT -5

Sorry for the delay guys but here they are, finally. I was doing 3 things at once. The power brake conversion, building a subframe to allow the use of a tow bar for those long trips until I am confident that all the mods I have done are 100% especially the hybrid drive axles, and a condenser support for the future AC install. A rather busy and packed front end. From right to left, Sub to fiberglass support, booster/master, sub to upper torsion brace, plug in so vehicle lights function when towing with tow bar, horn, battery, heater hoses, sub to upper torsion brace, Sub to fiberglass support. The white cannister is an old windshield washer bottle from a 76 VW bus, it is used for vacuum storage for the heater controls.    Diagonal brace is to support the front fiberglass. Toyota Corolla Master and brake booster secured to upper and lower torsion tubes using a home made mount and 2 1/8 muffler clamps.    Brake pushrod can be seen as well as the mechanical Toyota brake light switch. Brake switch sets pedal height.  Subframe travels all the way back to the seat pockets. It is also tied into the lower AND upper torsion tubes.  Crossbracing of the front subframe.  Steel heater lines, dedicated brake vac line and AC vac to storage cannister.  As you can see, ground clearance with the tow bar is at a premium.   The piece that joins the sides of the subframe at the front of the car will eventually become the lower support for the AC condenser. Still to come are photos of the modified Toyota brake pedal. |

|

|

|

Post by Dan MacMillan on Jun 6, 2013 21:10:22 GMT -5

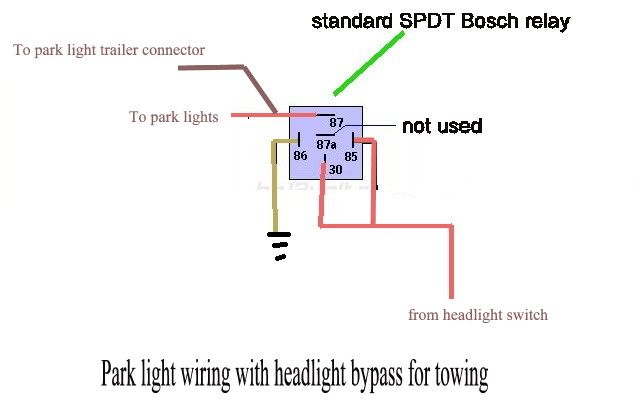

Headlight/park light modification to allow towing with park lights and no headlights. Powered from tow vehicle.  |

|

|

|

Post by Dan MacMillan on Jul 7, 2013 18:51:53 GMT -5

bump just for Skippy

|

|

|

|

Post by skip20 on Jul 7, 2013 19:17:24 GMT -5

Thank you. I must have missed this update.

Was hoping to see how/when you did it.

|

|

|

|

Post by Dan MacMillan on Jul 8, 2013 18:01:15 GMT -5

simply made a bracket to mount the booster to the front of the torsion beams. Muffler clamps work great to put things on the beam. Floor mounted pedal assy shifted 5" to the left. Pushrod goes between the steering box and the left shock tower. Brake sw mounts to the pushrod and presses against the outside of the front firewall. 4 wheel disk, no proportioning valve is used.

|

|