zaucy

Full Member

Posts: 127

|

Post by zaucy on Dec 19, 2012 0:22:09 GMT -5

If there is another thread covering this topic on the Bradley forum, please link me to it, I couldn't find any in the search. So the deal is my font suspension is completely bottomed out when the car is sitting. The car's suspension was like this when I bought it. I have been searching online, but the only two options of suspension I can seem to find is either fixed torsion leaves with set screws, or adjustable set screws like the following:  The front end on my Bradley GT 2 is adjustable, but I cannot find anyone with a similar front end online. Here it is:  Only the top torsion leaves adjust, and as far as I can tell it is adjusted to the max limit for max ride height. Also the set screw for the top torsion leaves looks way out of place compared to a standard Karmann Ghia front end. I'm not sure if this is normal, but here are my trailing arms when disconnected from the spindle:  Should the top trailing arm be angled up at it's natural state?? That doesn't seem correct to me. I feel like my only problem is how the top torsion leaves are oriented. If anyone could help me with this problem I would be very appreciative!!!!!!! |

|

|

|

Post by jspbtown on Dec 19, 2012 10:21:09 GMT -5

Thats an old time Select-a-drop adjuster. It will work just fine. You can crank your front end up by turning that center threaded rod. Just add some lube to it before you start turning. I would also take any load off of it (ie: jack the car up..make an adjustment, set it down, repeat as needed). Some good reading: www.thesamba.com/vw/forum/viewtopic.php?t=143094&start=100 |

|

zaucy

Full Member

Posts: 127

|

Post by zaucy on Dec 19, 2012 12:17:50 GMT -5

One thing that still concerns me, however, is the position of my top set screw. As you can see in one of my pictures it's pointed down towards the center of the car. Looking at this guys front end off the samba with the same adjustment system:  you can see both set screws are pointed upward toward the front of the car, a complete 180 degree difference. Not to mention every other front I have seen online is oriented upward toward the front of the car. Also, I already have cranked the adjuster so the top adjuster arm is as high as the gas tank permits. Am I right thinking the higher the adjuster arm is the higher the car's ride height is? Even at it's max adjustment the car is bottomed out. I plan on lowering the top adjuster arm to see if maybe I have the directions mixed up. |

|

zaucy

Full Member

Posts: 127

|

Post by zaucy on Dec 19, 2012 13:12:39 GMT -5

Correct me if I'm wrong, but it seems like there is just an inherent issue in the Bradley gt 2 design and this type of front end. I can see that the top adjuster arm still has an inch to an inch and a half of room to ride up the threaded bolt, which if I continued to raise it I think that would fix my suspension problem. However, my top adjuster arm is pressed right up against the gas tank and there's no way I can take it any further.

Does anyone else on the forum have this particular front end on their Bradley GT 2? Did you have this problem? how did you fix it?

Thanks

|

|

|

|

Post by jspbtown on Dec 19, 2012 15:20:53 GMT -5

It has nothing to do with the front end. people use the link style all the time. In fact many people prefer it.

If I recall correctly the select-a-drop only really moves one set of torsion leaves. The bottom set are not adjusted. In order to raise the vehicle the upper arm of the select-a-drop needs to move up. In your case it will rotate that grub screw away from the access plate that it is currently touching.

|

|

zaucy

Full Member

Posts: 127

|

Post by zaucy on Dec 19, 2012 15:50:26 GMT -5

Right, so since the upper arm of my select-a-drop system can no longer move up due to hitting the gas tank and my car still bottoms out, does this mean I will have to do some modification to the front end or move the gas tank?

|

|

|

|

Post by jspbtown on Dec 19, 2012 15:56:56 GMT -5

Can the tank be moved forward slightly?

If not you can remove the front end and reposition the upper bracket (cut off, rotate downward & re-weld) or

You can get a new beam with avis style adjusters. I think the select-a-drop kinda butchers your top tube so I don't know if you can remove it and then weld in some avis style adjusters.

Or you can get some raised spindles.

|

|

zaucy

Full Member

Posts: 127

|

Post by zaucy on Dec 19, 2012 16:03:52 GMT -5

I wasn't really sure if raised spindles were made, I didn't look for any, but I have only heard so much about drop spindles. I was actually planning on repositioning the upper arm just how you suggested. I'm glad you mentioned it, that only reassures my idea now, thanks. I have a friend with a machine shop so I'm going to get to work on removing the front end and then have him reposition the upper arm for me.

Thanks

|

|

|

|

Post by Wyn on Dec 20, 2012 22:00:46 GMT -5

My GT2 front end is a little low but I think it is from using a king pin torsion assembly. the rear end is a little bit high, I used a IRS rear torsion assembly that was removed from a dune buggy and it may need to be reset one splined down on the torsion bar. Although I do like the rake look of it. I maybe interested in the raised spindles if they are available. I did web search for raised spindles and all I could find was the lower spindles. Questions; Is that a king pin torsion assembly with ball joint suspension arms? A king pin torsion has straight shock arms, and the ball joint torsion has what I would call a cobra head for the upper shock mount.  Wyn |

|

zaucy

Full Member

Posts: 127

|

Post by zaucy on Dec 20, 2012 22:37:21 GMT -5

No, it's the ball joint torsion assembly with the "cobra heads." I literally have never seen my "select-a-drop" system up until jspbtown had directed me to that Samba thread; is this adjustment system why you thought it was the king pin torsion assembly?

For anyone interested I finally got the adjustable arm removed from my front end and had a friend cut, re-orient, and re-weld the upper bracket to my select-a-drop system. When I have everything finished I will post a handful of pictures and description.

|

|

zaucy

Full Member

Posts: 127

|

Post by zaucy on Dec 22, 2012 3:20:18 GMT -5

So, as said before, I cut off the top adjuster arm in my front end, re-positioned it, and re-welded it back on. Here is my front end and ride height, pre-modification: Notice the adjuster arm and grub(set) screw make a 90 degree angle.  Notice the top trailing arm (the arm connected to the only adjustable set of torsion leaves) is angled upwards in it's non-torqued state.  This is kind of a hard picture to really see, but nearly the whole tire is tucked away in the fender. All of these pictures were taken when the top torsion bar was adjusted for as max height as the gas tank permitted. Post-modification:   Notice now how the grub(set) screw is only a few degrees apart rather than 90.  Now the top trailing arm is angled downwards.  Maybe it doesn't look much different from the previous picture, but you can tell most of the tire is out of the fender now. All these pictures were taken when the adjuster was at it's minimum adjustment. If anything, the suspension is no longer bottomed out and the ride is MUCHHHHH better now. Just gotta get my new shocks in the mail and it will hopefully get even better.

So in a nut shell: the select-a-drop system was meant to be adjusted from the car bottomed out to the car riding high. However, because of how the Bradley GT2 was designed, the gas tank was in the way of the adjuster (my suspension could only be adjusted from bottomed out to about 10-15% of the max adjustment). What I did was make that 10-15% of adjustment go from bottomed out-10-15% the max height to medium ride height-higher ride height. |

|

zaucy

Full Member

Posts: 127

|

Post by zaucy on May 21, 2013 18:06:40 GMT -5

So instead of making a new thread, I decided to add to this one.

Right now my rear suspension is uneven so I plan on fixing that in the near future. One issue I have is the rear wheels bouncing up and down too much hitting the rear fenders (because I have a 4" spacer on the rear wheels). I plan on adjusting the suspension so I have a stiffer ride in the rear and the wheels won't bounce as much. Right now I am thinking of placing sand bags on the butt when jacking the spring plates back into place to get a higher torque on the torsion bars. Assuming my torsion bars in the rear are all fine (i.e. no structural cracks), will the added torque be fine for the torsion bars?

I was thinking somewhere between 75-100lbs of added weight on the back. I just don't want to torque one of the torsion bars past the breaking point.

Thanks

|

|

|

|

Post by cocacoladodge on May 22, 2013 10:34:45 GMT -5

I wondered what that adjuster was on my blue 74 GT. Oh well, I just used some 4 setting coilovers on the third highest setting to fix the height on the silver 76. think i'll take the front setting back down to either 2 or 1.

Thank you for bumping this back into use!

|

|

zaucy

Full Member

Posts: 127

|

Post by zaucy on May 24, 2013 15:48:05 GMT -5

So instead of making a new thread, I decided to add to this one. Right now my rear suspension is uneven so I plan on fixing that in the near future. One issue I have is the rear wheels bouncing up and down too much hitting the rear fenders (because I have a 4" spacer on the rear wheels). I plan on adjusting the suspension so I have a stiffer ride in the rear and the wheels won't bounce as much. Right now I am thinking of placing sand bags on the butt when jacking the spring plates back into place to get a higher torque on the torsion bars. Assuming my torsion bars in the rear are all fine (i.e. no structural cracks), will the added torque be fine for the torsion bars? I was thinking somewhere between 75-100lbs of added weight on the back. I just don't want to torque one of the torsion bars past the breaking point. Thanks Bump on this quesiton |

|

|

|

Post by Dan MacMillan on May 24, 2013 16:06:45 GMT -5

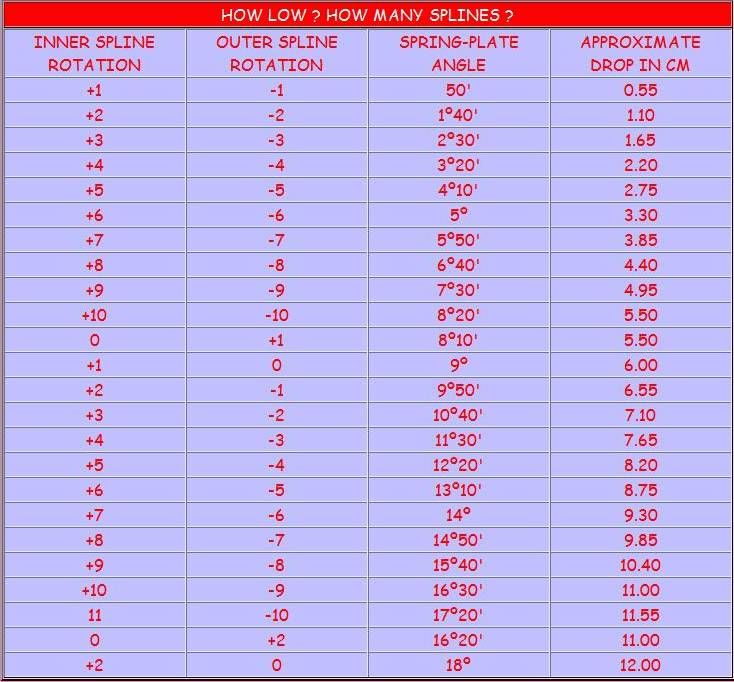

Put the car on stands level ground and level side to side. Front wheels straight ahead. Release the tension on both sides do not remove the bars or spring plates. Measure the angle of the spring plate on the good side. Measure the angle on the bad side. Subtract the two. Adjust the bad side to match by changing the position of both the inner and outer spline. If it is a swing axle it will be easier as thje longer splring plate will make loading the torsion bar easier. If IRS, bolt an extension onto the spring plate to make it easier. Use a floor jack under the end of the spring plate. Fasten a chain from the front axle of the floor jack to the upper shock mounting on the chassis. Jacking up will raise the plate and pull down on the chassis. The following chart explains the degree changes. The lower the spring plate is wjen tension is released , the higher the car will sit. Bouncy is caused by bad shocks not springs.  I use a level app on my cell phone to do the measuring. |

|