|

|

Post by horen2tas on Mar 25, 2012 17:45:37 GMT -5

The PO on my GT2 ran a stainless braided gas line from the tank in front along the outside under side of the chassis (beside the body mounting bolts) to a filter in the drivers side rear fender and then rubber line to the fuel pump (standard mechanical) and then to the carbs. Last week the braided sprung a leak and I had a friend replace it with a braided hose he picked up at a swap meet (15' long) that also turned out to have a leak so we ran a stainless tube through the tunnel from the front center of the tunnel head and exiting the back along the drivers side transmission mount.

My question is on the rubber connectors from the tank in front and from the stainless tube in back there are quite a few twists and turns up and down.

Is there an Physics Laws that won't allow for ups and downs in the line if the gas is going to flow?

I don't want to install an electric pump but I'm having some trouble with the motor cutting out.

|

|

|

|

Post by Dan MacMillan on Mar 25, 2012 18:14:31 GMT -5

The only law of physics you need to know is gas will not flow through a pinched line. No problem with the ups and downs. As for using stainless tube, Stainless is very brittle and should not be used, especially in the tunnel. When it cracks the tunnel will fill with gas until it finds a way out. One wrong spark or heat souce and you can kiss your car goodbye.

The previous owner had the right idea of running it along the outside of the frame [just like modern cars] but he should have used regular 5/16 steel tube {roll of 5/16 brake line works great and is easily shaped} with 5/16 neoprene fuel hose on the ends. Slightly flare the ends {first stage of a double flare} and clamp every connection. By running under the car if you get a leak it will safely hit the ground.

|

|

|

|

Post by jspbtown on Mar 25, 2012 18:21:51 GMT -5

I agree with Dan. NAPA sells those nice long rolls of that line. Don't forget lots of insulated clamps.

|

|

|

|

Post by kensaw210 on Mar 25, 2012 18:25:36 GMT -5

Since we are on gas lines and fuel pumps, I was thinking about an electric fuel pump are there and advantages to go electric. I now have a 2 barrel carb would it give me more power getting the gas to the carb at an even flow.

Kensaw210

|

|

|

|

Post by Dan MacMillan on Mar 25, 2012 18:51:31 GMT -5

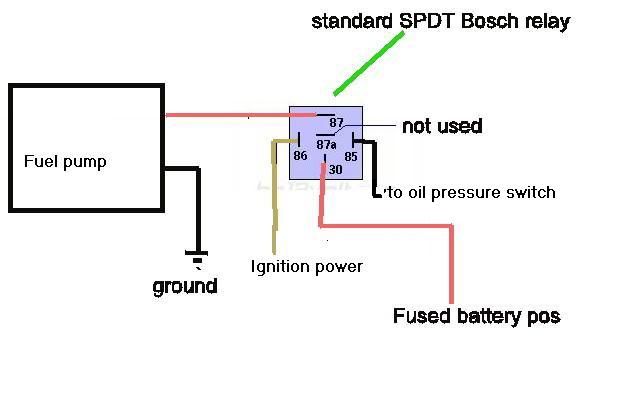

Won't affect power as the carb runs off of a reservoir of fuel under atmospheric pressure {gravity feed} It will reduce the chances of vapour lock in the lines. Make sure to wire it up with a relay that is triggered by your oil pressure switch. That way if you have an accident the pump will shut off if the engine stops. Make sure the pressure output is compatible with your carb. You may need a pressure regulator. Pump goes close to tank, filter before the pump. Standard bosch relay  |

|

|

|

Post by cocacoladodge on Mar 26, 2012 0:06:57 GMT -5

Dan, you have amazed me yet again. When I put an electric pump in my GT I was unable to find a good way to route the power to it. So as a temperary solution I wired in a toggle switch near the motor conpartment, and was intending on routing into the passenger conpartment on my next day off and have a switch behind the drivers seat. This sounds like a great idea.. the oil pressure gauge hookup that is.

So when I start cranking over I build pressure and kick on the fuel, unless I'm low on oil then it acts like a cut off so I Don't burn up the motor. Just like my generator, why didn't I think of that...

|

|

|

|

Post by Dan MacMillan on Mar 26, 2012 5:20:04 GMT -5

As the carb is full of fuel startups will. BE instant but will shut down soon after if the pump fails to turn on.

|

|

|

|

Post by jspbtown on Mar 26, 2012 8:24:32 GMT -5

Not oil pressure gauge....You must use the sender for an oil pressure light. The guage uses a variable resistance.

|

|

|

|

Post by Dan MacMillan on Mar 26, 2012 17:29:36 GMT -5

Just noticed I mentioned 5/16 for the size of the fuel line, that is what I use on my fuel inj cars. On a normal VW engine it would be 1/4".

jspbtown is correct.

oil lights use a switch and this is where you hook up. Electric gauges use a sending unit and will not work.

|

|

|

|

Post by horen2tas on Mar 26, 2012 21:59:12 GMT -5

Back to my original question re: stainless steel line through the tunnel.

How much time do you think I have before I can expect it to break apart?

B.T.W. I see a lot of applications of stainless on automotive web sights including fuel and brake lines.

I need some time to regroup and get the materials that I'll replace the s.s. set-up with but I'd like to be able to drive in the meantime.

|

|

|

|

Post by jspbtown on Mar 27, 2012 11:16:19 GMT -5

Your really have to secure any line within the tunnel very securely. You can try to secure it though the pedal cluster hole, the shifter hole, the ebrake hole, and the rear access hole. If you don't it will rattle and flex excessively and I bet it will both drive you crazy and crack within a few hundred miles.

Through those very small holes you need to take a section of split rubber hose, install it over the line and zip tie it to another tube nearby. Good luck with that. Most people cut several access holes in the tunnel to do it right. For that I assume you will have to remove your interior.

Your also have to find a way to get it up through the stock locations in the front and back with the body on and all the things (gas tank, engine, etc etc) that are in the way. Again...good luck with that.

Running a new line (any type of metal line) inside the tunnel is a pain to do when the body is totally off the car...never mind whgen its on.

|

|

|

|

Post by mj on Apr 14, 2012 12:08:17 GMT -5

Just my two-bits. My GTII gas tank is far forward. I run a 3/8" ductile aluminum fuel line wrapped with two layers of regular fuel line (1/2" + 5/8") which serves to protect the aluminum line from chafing due to vibration, and any 'lucky' stones, etc, which might find the line. The line runs along the outside chassis channel on the passenger's side, protected by the lip in the chassis. And I used a lot of aluminum clips to hold the line secure. I have a fuel filter at the gas tank, followed by an electric fuel pump (wrapped in sealed-cell aircraft foam) and in the rear I use a large fuel filter before the carbs. So I get doubling filtration, one to protect the pump, and another to be just certain the fuel is clean. The fuel pump I use. (I keep a spare onboard). vwparts.aircooled.net/Rotary-Electric-Fuel-Pump-3-25-psi-7mm-Fittings-p/rotary.htm "delivering 30gal/hr @ 3psi fuel pressure, which is the correct fuel pressure for Webers, Dellortos, and Kadrons, and all stock carburetors. " The fuel pump is on a kill switch left of the steering wheel. So is the ignition. I believe in kill switches. (One use is for when the engine has not run for a couple days - I will leave the kill-switch to 'off' which turns off the ignition and fuel pump, then crank the engine until oil pressure is established, then start it.) To wrap the fuel line covering the aluminum fuel line, just slit the composite hose and push it over the line under it as you install and clip the line to the chassis.  |

|